With the WASP TOUCH, we have automated our inoculations in logarithmic or linear mode, which allows us to reduce the use of consumables such as Petri dishes and tubes, while making our analyses faster, more reproducible, and easier to perform on a daily basis.

Loetitia Nicaud, Laboratory Manager

A few months ago, we were welcomed by Loetitia Nicaud, head of the microbiology laboratory at the Guinot-Mary Cohr group. The aim was to see how automation is used to increase productivity while improving working conditions.

Founded in 1972, the Guinot-Mary Cohr group is the leader in the field of beauty and professional institute treatments in France, “with 11,000 institutes worldwide, including 1,800 in France,” as Ms. Nicaud pointed out. The company is based in Dammarie-les-Lys in Seine-et-Marne and is renowned for its flagship brands Guinot and Mary Cohr.

A laboratory at the heart of quality control and innovation

Loetitia Nicaud described how her department works. The laboratory operates on two levels:

- Quality control : rigorous monitoring of products throughout their manufacture, right up to their release onto the market.

- Research and development : performing challenge tests, validating neutralizing diluents, and checking the microbial cleanliness of new formulations.

Faced with these numerous tasks, automation has emerged as an effective solution for optimizing processes. Loetitia Nicaud told us, “It’s a lot of work for a small laboratory, so we sought to improve our methods.”

Automate to increase efficiency

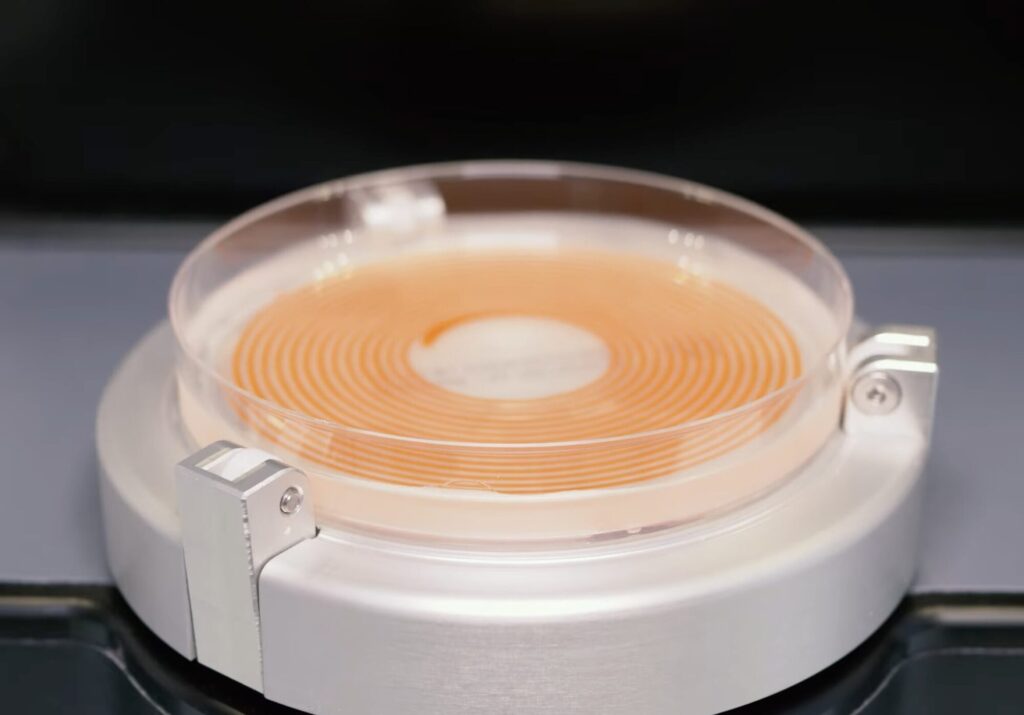

To determine the microbial concentration in a cosmetic sample, a inoculation step is necessary. Typically, this involves first diluting the extract to be analyzed. Next, the microbiological criteria to be met for the detection of a germ, such as E. coli, must be defined by inoculating a minimum of two successive dilutions onto the surface of different agar media in Petri dishes.

This step can be reduced in terms of both time and cost by using a spiral inoculator such as the WASP TOUCH. This device ensures automated and reproducible dilution inoculation in a matter of seconds on a single Petri dish thanks to two modes:

- Logarithmic mode : three dilutions in the same plate, reducing the number of consumables (plates, tubes, media) and consequently, waste

- Linear mode : precise dispensing of a single dilution for optimal colony counting (challenge test)

Another major advantage of this type of machine is the significant reduction in musculoskeletal disorders (MSDs), which are common among technicians. “MSDs are very important in a laboratory.” By automating repetitive inoculation tasks, this equipment helps to limit repetitive movements and uncomfortable postures, which are key factors in the development of MSDs and represent a major challenge in laboratories.

Finally, for Ms. Nicaud, it is clear that this “easy-to-use and low-maintenance” automated system is now indispensable for research and development analyses at Guinot. A major change that combines performance and ergonomics in the laboratory!

We would like to thank Loetitia Nicaud for this interview, as well as the entire team at the Guinot-Mary Cohr laboratory for their warm welcome and availability.

You would like to learn more about the

WASP TOUCH spiral plater :

👉 Would you like to learn more about our WASP TOUCH spiral plater? Contact us now:

Please complete the form below to contact us:

"*" indicates required fields