Three models, one reliable solution

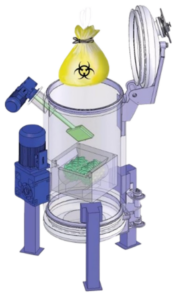

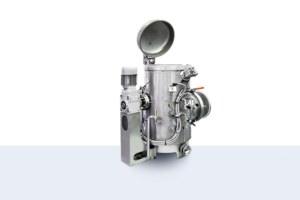

The EcoDASRI™ is a compact system that combines shredding and sterilization of infectious healthcare waste (IHW) in a single unit. Built with stainless steel, it ensures safe processing within a sealed chamber, with no direct contact with the waste during the cycle. The T100, T150, and T300 models allow treatment of 100 to 300 liters per cycle, meeting a variety of capacity requirements.

Efficient and eco-friendly

EcoDASRI™ systems use saturated steam between 130 °C and 138 °C, ensuring a 10⁸ sterilization level (Geobacillus stearothermophilus) in under 30 minutes. Thanks to its patented technology, the process achieves up to 80% volume reduction and 40% weight reduction, depending on the type of waste. The device is designed to minimize liquid discharge, maintain low water and energy consumption, and emit no atmospheric emissions. These performance features make it an environmentally friendly solution, aligned with today’s sanitary and ecological standards.

Fully automated, simple, and safe

Operation is designed for quick and risk-free handling: the operator loads the waste via a waist-height access point (T100) or using a lift system (T150/T300), then starts the cycle through a multilingual touchscreen interface. The machine then manages all stages autonomously—shredding, sterilization, cooling, unloading—with traceability ensured by automatic cycle report printing, in compliance with regulatory requirements.

A solution adaptable to any environment

Delivered with a boiler, compressor, water softener, and unloading trolley, the EcoDASRI™ systems integrate easily into laboratories, hospitals, or industrial facilities. The T100 can be installed in just two days and can operate with an existing external boiler. The T150, the first model to include a lubrication module, offers greater power, while the T300 meets high-load demands with a 40 kW generator and a 500 L steam capacity. Several customizable options (horizontal opening, compatibility with wheeled bins) make it possible to tailor each installation to specific needs.